Key Features:

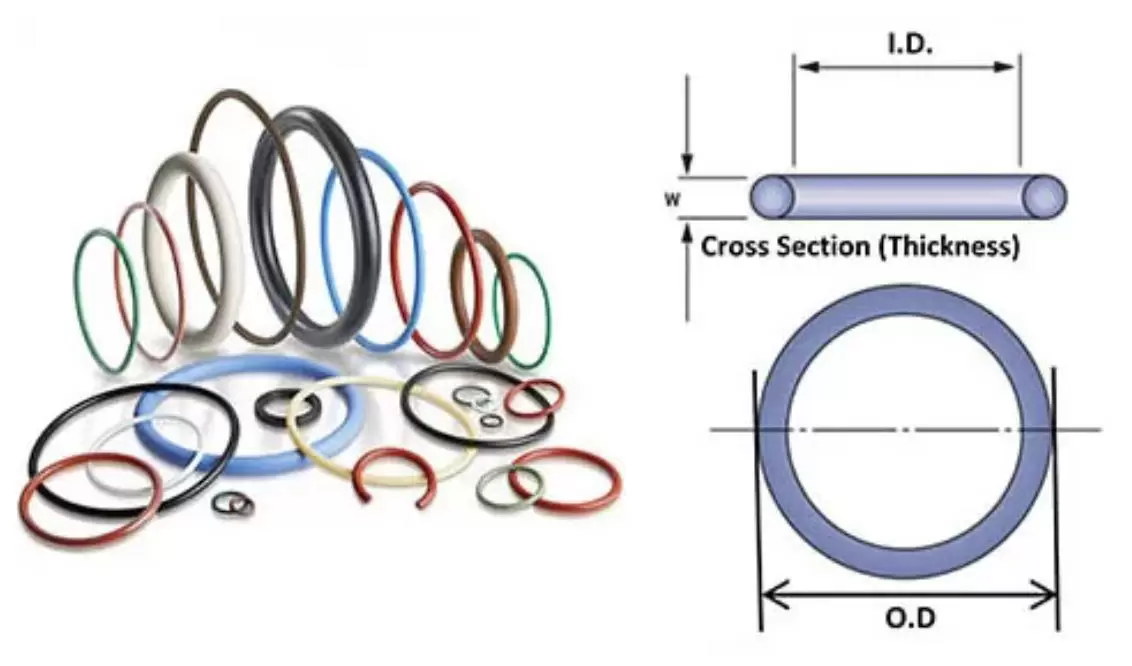

Material Options: NBR, EPDM, Silicone, FKM, FFKM bonded with stainless steel, carbon steel, or aluminum

Temperature Range: -60°C to +320°C (depending on rubber type)

Hardness: 40–95 Shore A

Certifications: RoHS, REACH, FDA, UL compliant

Custom shapes, thicknesses, and bonding designs available

Applications:

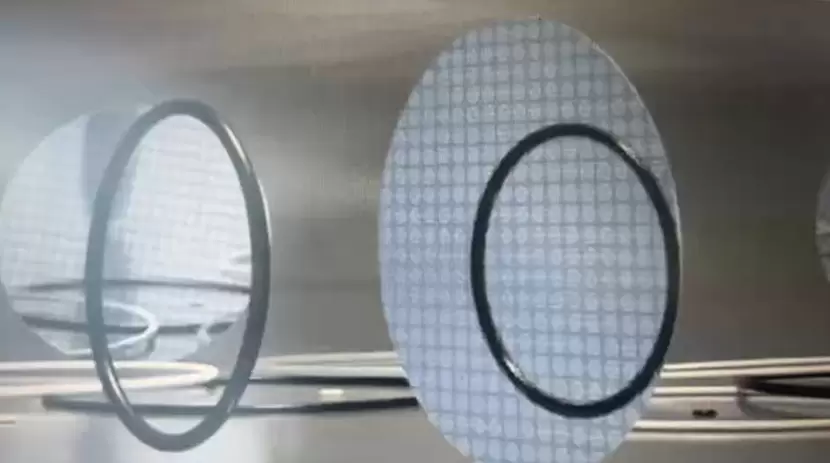

Metal bonded rubber seals are widely used in automotive braking systems, engine mounts, shock absorbers, compressors, pumps, valves, and hydraulic equipment. They also play critical roles in oil & gas pipelines, HVAC systems, electronic housings, and industrial machinery, providing secure sealing and vibration damping between rigid metal interfaces. In semiconductor and precision instruments, they ensure contamination-free and high-purity sealing performance.

Advantages:

Strong chemical and mechanical bonding between rubber and metal

Excellent resistance to compression set, wear, and corrosion

Stable sealing under high pressure and dynamic loads

Custom designs for various shapes, materials, and operating conditions

One-stop solution from bonding technology development to finished products

Our metal bonded rubber seals deliver reliable, durable, and customized sealing solutions for high-demand industries where performance, precision, and longevity are critical.

Colors:

Packaging: