Technical Requirements:

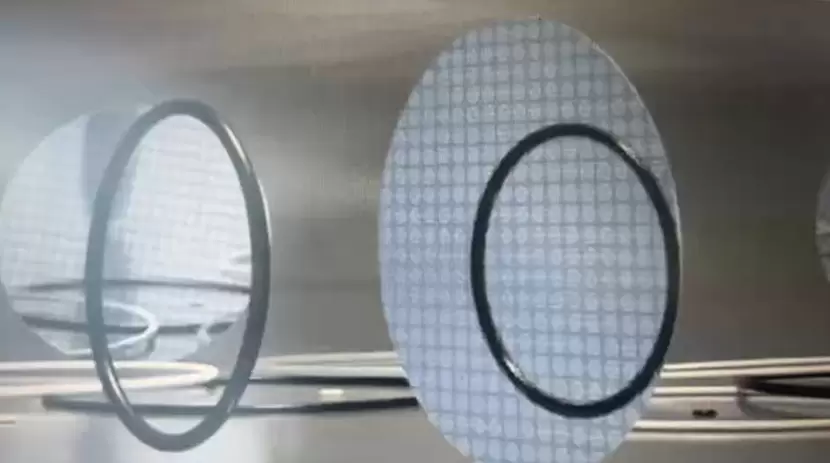

Our proprietary one-piece molding and segmented vulcanization process eliminates visible seams, ensuring superior structural integrity and durability

The segmented vulcanization technology guarantees a seamless, full-circle product, with no joints, enhancing product stability and extending its service life

Offers superior tensile strength and elongation at break, ensuring the product's flexibility and resilience under high stress

Our technology is more robust than conventional seals made with glue connections, providing a stronger, more reliable seal that can withstand harsh operating conditions

Ideal for large cavity applications with inner diameters exceeding 3 meters

Key Features:

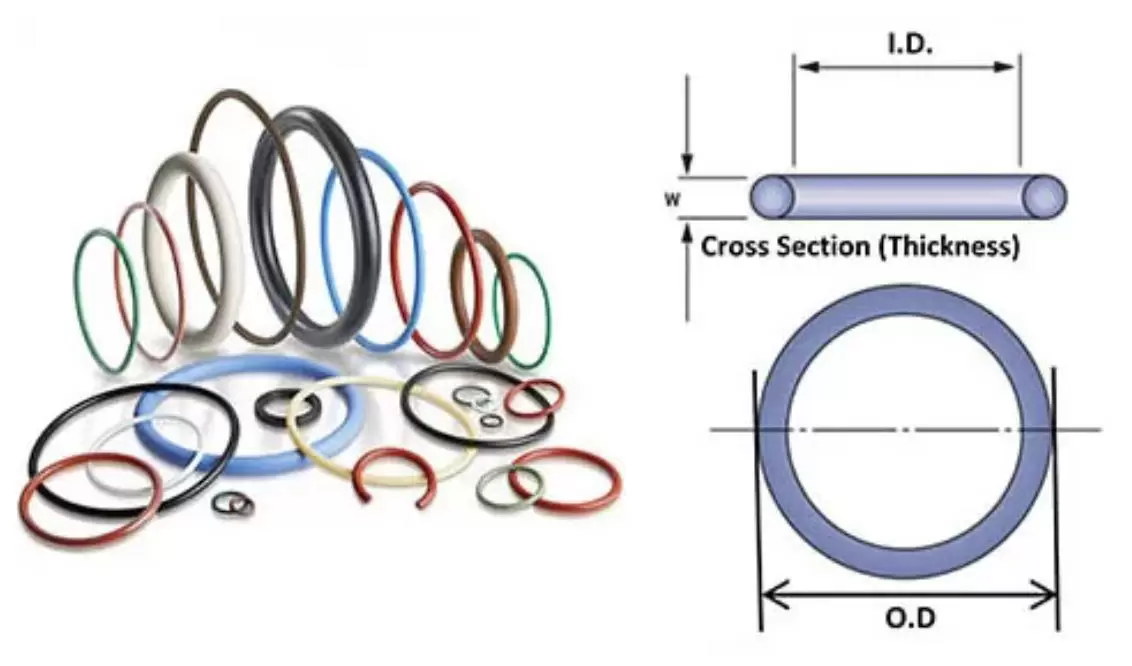

Material Options: EPDM, FKM, NBR

Temperature Range: -40°C to +250°C (material dependent)

Hardness: 50–90 Shore A

Compression Set Rate: Low

Strength: High tensile strength and impact resistance

Customization: Available in non-standard sizes, with fast delivery options

Certifications: RoHS, FDA, UL compliant

Colors: Black, Brown custom colors available

Applications:

Heavy-duty industrial machinery and equipment

Large-scale pumps and turbines

Offshore platforms, mining machinery, and oil & gas extraction systems

Construction vehicles and large manufacturing equipment

Advantages:

Seamless and Durable: Patented one-piece design with no visible seams ensures a strong, reliable seal

High Strength: The segmented vulcanization process enhances tensile strength and elongation at break, making the seal more durable and flexible

No Weak Points: The absence of glue or joint connections eliminates potential failure points, ensuring long-term reliability

Customizable: Full range of sizes available, with fast turnaround for custom and non-standard sizes

Our super large size seals provide robust, high-performance sealing solutions for large-scale applications, offering a stronger, longer-lasting seal than traditional glued products, reducing maintenance and downtime.

Colors:

Packaging: