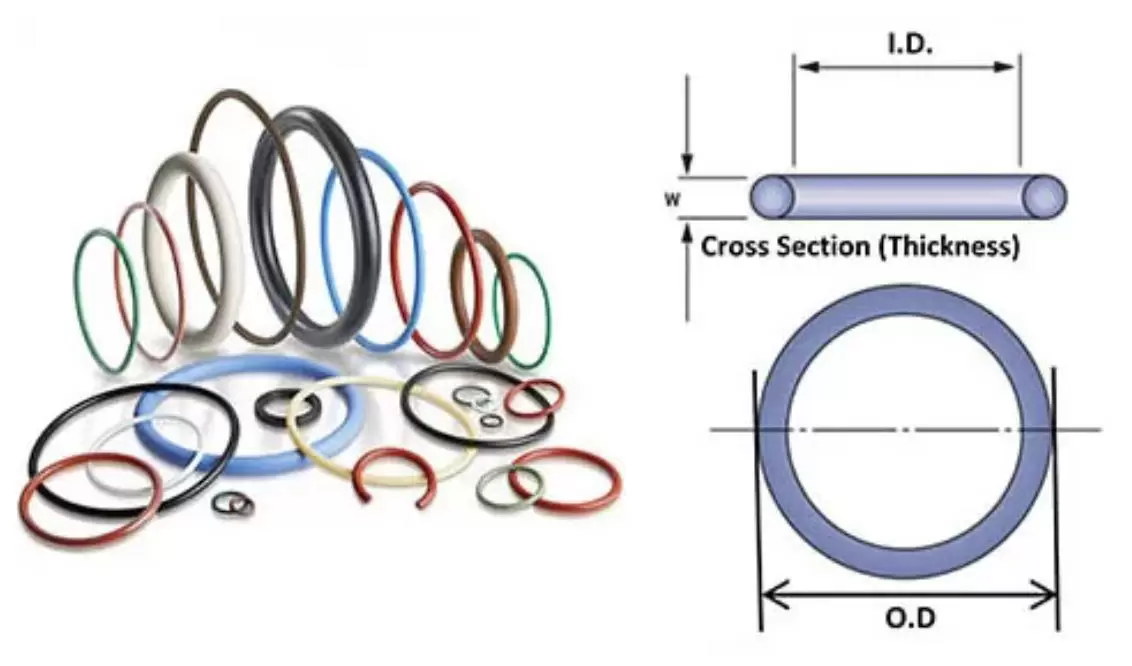

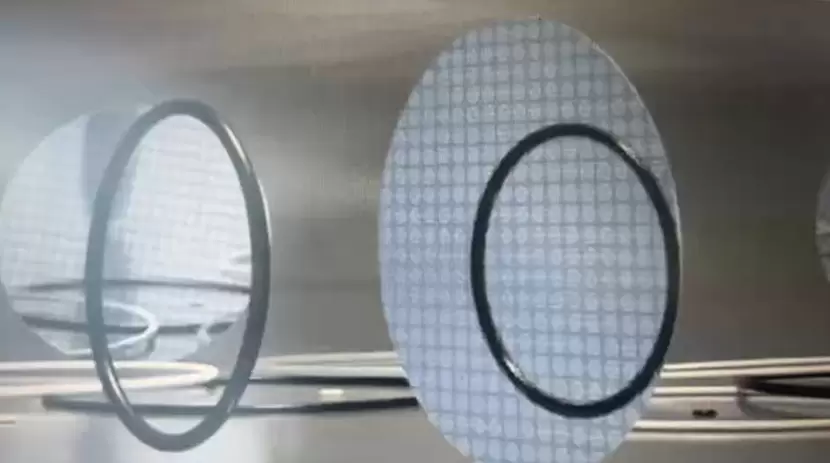

Material Options: NBR, EPDM, Silicone, FKM, FFKM bonded with stainless steel, carbon steel, or aluminum

Temperature Range: -60°C to +320°C (depending on rubber type)

Hardness: 40–95 Shore A

Certifications: RoHS, REACH, FDA, UL compliant

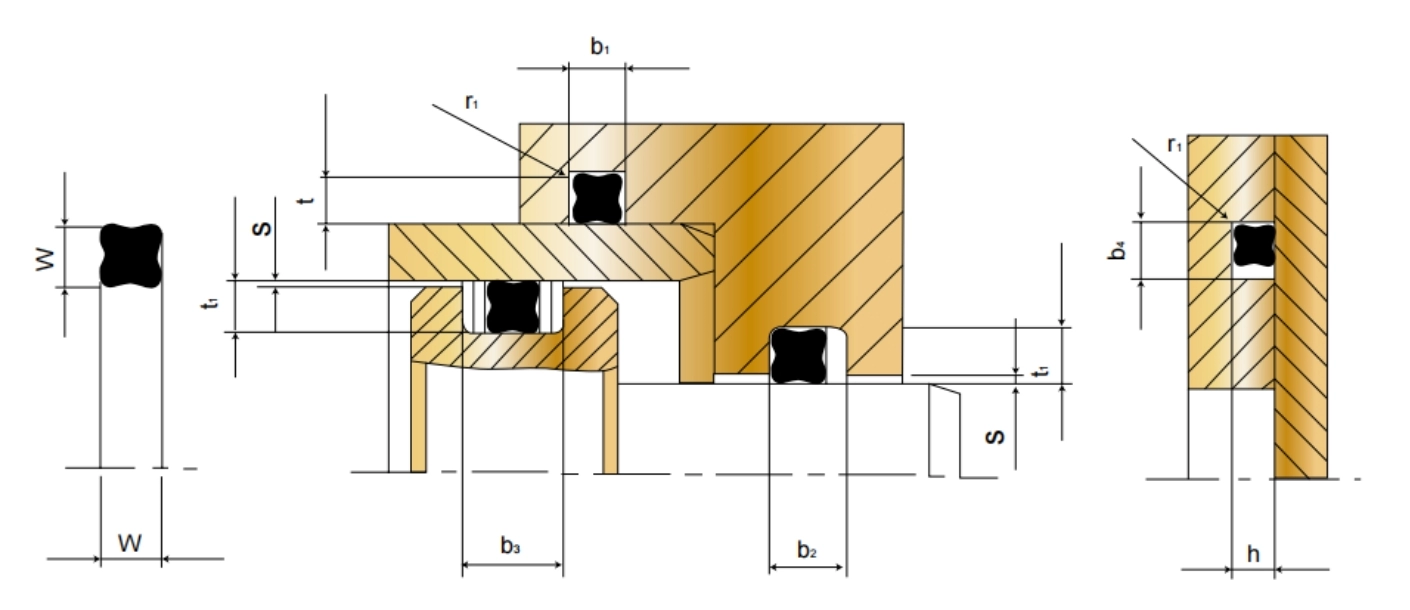

Custom shapes, thicknesses, and bonding designs available

Certifications:

Colors:

Packaging: Bulk, individual bags, or OEM branded