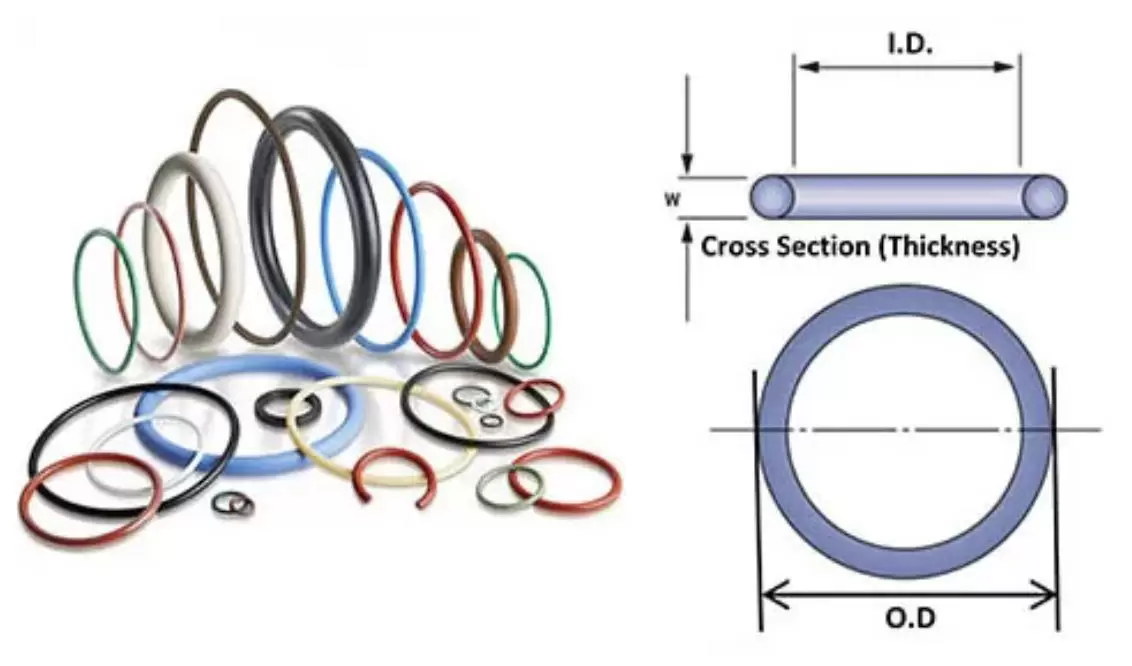

Material Options: NBR, EPDM, Silicone, FKM, FFKM

Temperature Range: -60°C to +320°C (material dependent)

Hardness: 20–90 Shore A

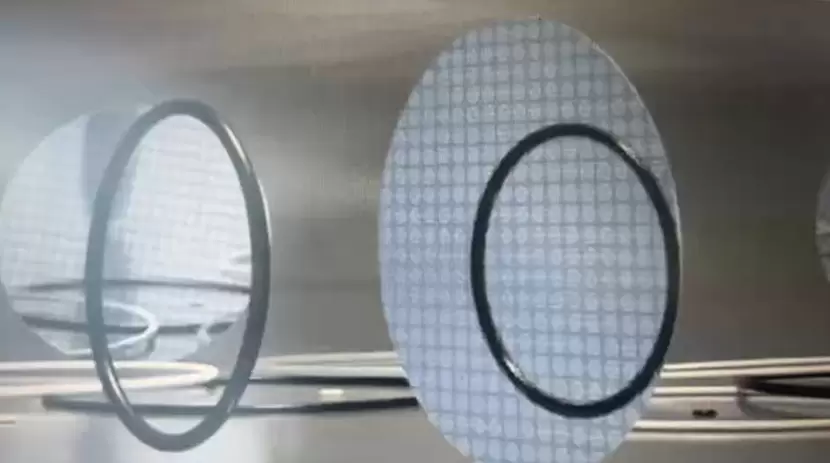

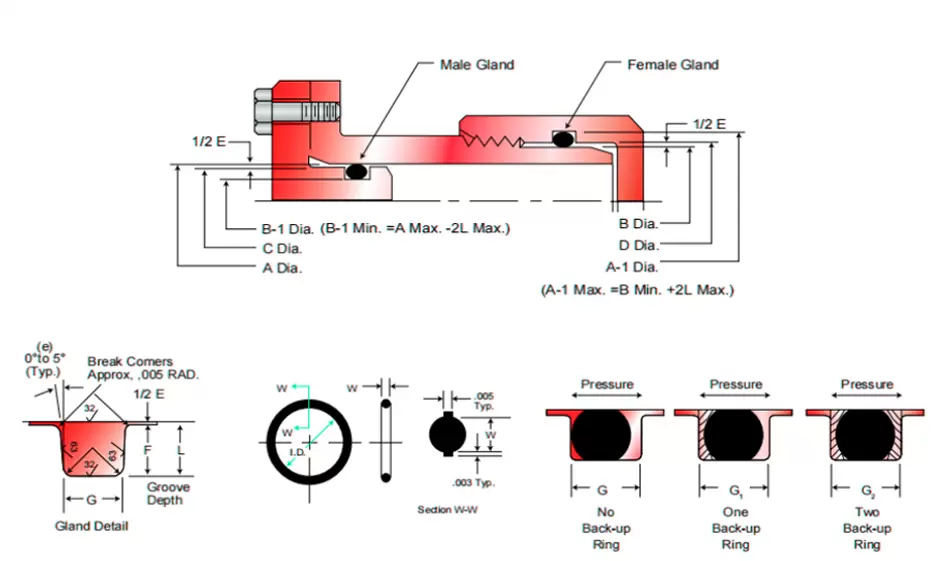

Standards Available: AS568, ISO 3601, JIS B 2401, customized sizes、

Design Flexibility: O-rings, X-rings, U-rings, V-rings, gaskets, non-standard geometries, complex profiles

Certifications:

Colors:

Packaging: Bulk, individual bags, or OEM branded